JaySam

Toyota Advanced Member-

Posts

100 -

Joined

-

Last visited

JaySam's Achievements

Rookie (2/14)

-

Rare

-

Rare

-

Rare

-

Rare

-

Recent Badges

-

New join dolphin owner and sunrader interior height wanderings

JaySam replied to chadsam's topic in General Discussion

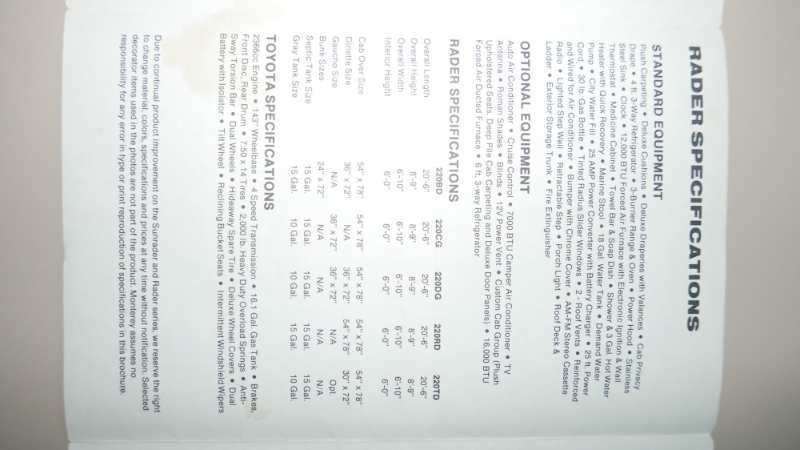

From the specs sheet I have it looks like all interiors are 6'. However pre 1987 there was no roof supports added so a lot of these have collapsed or sagged over the years. I believe (and maybe Linda can confirm?) that '87 and onwards there was at least 1 if not 2 roof support beams that helped prevent the roofs from sagging. On my '85 it was sagging at least 5-6" although I was able to regain that by rebuilding the roof with metal supports. Hope this helps -

I don't think ABS affects anything, I swapped in a 4.88 from a 94 4runner with abs and I just cut the wires at the sensor and had the shop put the gears in. I believe anything from 85-95 with work for the 3rd member but not positive about the year spread. Any pickup or 4 runner 3rd member should work. I found this page useful for locating a used 3rd member and making sure it would work https://lcengineering.com/toyota-4x4-gears-and-differentials/ There used to be a wonderful junkyard in Denver called the Yota Yard but unfortunately they have gone out of business. You might try calling LC Engineering and asking them where to source a used 3rd member, when I was at yota yard looking for one last year I called em up and they talked me through how to identify what I need on the spot. Very helpful guys. And the 4.88 upgrade made a world of difference, overdrive actually works!!

-

Can you calibrate the temp sensor? I thought it was just a passive sensor and nothing you can adjust or calibrate on it I'm not getting wild readings while warming up, the pic is showing the gauge after fully warming up and driving around for a few. It maintained itself where its at I just figured it would be sitting in the slightly-below-halfway mark like it always used to instead of up near the red line like the pic shows. I'm going to try shielding the sensor from the manifold heat and see if that changes the reading at all

-

I don't understand why the coolant temp in the block would be so much hotter than the coolant temp at the intake, but maybe part of the temp is coming from the block itself? The reason I'm trying to install a secondary gauge is because twice now the auto gauge sensor hasn't kicked on until after the t-stat opened and it gave me concerns about it going out so I wanted to add a backup. It's a new sensor I bought from LC Engineering. I've thought about adding a t at the intake port but it'd be nice not to drain and refill the coolant system again haha. I guess I'm still just confused on why the temp sensor on the block would read so much higher than the temp sensor on the intake. Is the coolant that much hotter in the block before it gets to the intake?

-

I recently had a new motor installed in my Sunrader and when I did I had the mechanic add an Auto Gauge Water Temp gauge so I could monitor temps a little more closely. When he installed it he just replaced the factory temp sensor with the auto gauge one so the dash gauge no longer worked. I wanted to re-hook up the dash gauge so I could have 2 gauges and more closely monitor the temp and when I might be treading into dangerous territory. Today I installed a temp sensor into the block drain plug location and reconnected it. The gauge works but is reading extremely high, almost into the red even though the actual temp on the auto gauge is only 180. I'm guessing this is because of the location of the sensor but I don't know, would this be the case? Could the exhaust be heating up the sensor or wire maybe and making it read high? Or is there a better location for a secondary temp gauge sensor? I have the upper radiator hose manifold kit to install the sensor there and had it there but it read hot as well and only kicks on after the t-stat opens so i was hoping for a spot that would read the block temp.

-

Ok well it's been quite awhile since I've posted any updates so here we go. Long story short I've now got a new motor, radiator and I swapped out the rear end to 4.88's. It drives like a completely different vehicle now, and by that I mean it almost drives like a regular truck. I can use all of my gears now including overdrive, and the motor seems to work much less and is much happier overall. I'm just getting past the first 500 miles on the motor so still have some time to break it in and everything but so far I'm really pleased with how it turned out. I weighed it a few weeks ago dry and it came in at 4670lbs. The door sticker says 5500 so if that was accurate I've managed to drop over 800lbs out of this thing. Of course the bathroom and other appliances were probably a good portion of that but I also worked hard to try to not overbuild inside and keep a mind towards weight which I think has paid off. I also relocated most of the weight from the rear of the camper to sit over the axle instead; the water tanks and fridge are located directly over the axle, the furnace moved in front of it and just the battery and propane tanks sit behind it. Moving a lot of the weight from the very back of the rig to sit directly over the axle has really improved the handling and drivability of the camper as well. Inside I've managed to get most of the major things done; I still need to finish off a few things and put the hardwood floor back down but I would say a good 80% of it is completed. I still have plans for new cubbies, shelves and cabinets for the sink area and on top of the counter next to the bed but the major stuff is built and installed. Overall I'm pretty pleased with how it has turned out and the rig I now have for some sweet adventures but it's certainly been a long road. When I purchased it back in 2019 my intention was to buy something I could just use and enjoy, I never intended to rebuild an RV from front to back top to bottom. But here I am a few years later and I'm glad I've stuck with the project and made it to the other side of it. Thank you to everyone on this site for the information, suggestions and tips for rebuilding these things and all the knowledge and expertise everyone has provided, it's been a huge help throughout this process and its hard to imagine trying to wade through the rebuild of one of these things without it. Thanks again to everyone who contributes and shares their knowledge and experience.

-

Ok yeah that's kinda what I thought but good to know, thanks for the info and help Maineah. I think as long as the motor seems ok I'll have them do the head gasket, machine the head, timing chain, guides and potentially cover if it's been worn down and a water pump. Thanks everyone for the advice and knowledge, I'm feeling much better than I was a few days ago lol.

-

Ok good to know, thanks for the advice and info Fred! I'll probably have them do a water pump even though I can do it myself later, and hold off on a oil pump for now. Are there other components or parts that I should have them check while we're this deep into the motor? Budget is a concern but less so than making sure I do things right

-

Yeah I figure if i'm going to get the head gasket done it's time to do the other routine maintenence that will be needed at some point anyways, so now I'm thinking of having the timing chain, oil pump and water pump done as well. Although maybe the oil pump is overkill? What's a usual lifespan on one of those? Water pump and oil pump I could also do myself at some point down the road. Is the dual row upgrade worth it if I'm replacing the plastic guides to metal? Is it mostly helping prevent the chain stretch and slap that happens with a single row? I guess I'm not clear on why upgrading to dual row is necessary but would love to learn

-

I thought the reason was the different metals between head and block and old felt gaskets that don't work well to compensate the different expansion/contractions of the two metals. My understanding was the MLS gasket solves this issue; is there something else you may be referring to? If i'm having the head gasket done seems like it makes sense to do the timing chain now as well? I don't think it's ever been replaced so seems like a good time for a new chain and steel guides? Are there any other things I should maybe consider while I'm in there? Thanks everyone for the help and suggestions!!

-

Hey Everyone, So I was driving through Wyoming when the head gasket went out on my rig. I have a 1985 Sunrader with a 22re with 85,000 miles on it. I'm looking for some advice on what to do going forward. Since doing a head gasket is such a big job and requires so much labor I'm wondering if it's worth just having the motor rebuilt at this point? Or potentially have a new motor installed? The motor seemed decent before the head gasket blew, I had tested the compression maybe a year ago and it was at 135-140psi across all cylinders. But she did get extremely hot and was out of coolant when the gasket blew and I got it pulled over, I'm slightly concerned about warped/cracked head although I was able to limp it to a shop after it cooled down and I refilled the radiator. I'm wondering if I should be looking into rebuild/replacement options or if i should just have the shop do the head gasket, check everything else out while in there, replace what's worn out and move on with the motor I've got. I'm on the fence with this decision and would love some advice on the matter if anyone's got some. Thanks!