Wade

Toyota Advanced Member-

Posts

73 -

Joined

-

Last visited

Content Type

Events

Profiles

Forums

Gallery

Everything posted by Wade

-

That is interesting. I wish I knew what Jerry at 22re Performance did to ID it. All I know is that the tire shop could not get the correct emergency brake cable but Jerry used the VIN and got the correct one in a sealed Toyota parts bag. Somehow Toyota made a part for the 6 bolt axle for my 85 VIN. The non-toyota part that the tire shop ordered probably based off the fact that is was a 1985 truck, was not the correct part for the axle that is on the truck. Whatever is on there, if it is a 4.10, then either the gear calculator I used is wrong or the owners manual is a misprint, or the actual redline is 7500 rpm. Then again, if the 6 bolt axle was not from Toyota then the owners manual would only be correct if it was the same ratio as whatever Toyota installed on the trucks covered by the manual. I have the build sheet supplied by toyota to the coachbuilder. That doesn't say what axle was installed but only that the GAWR is to be 3700lbs for the rear with 2050 for the front but only 5500 total which doesn't make a whole lot of sense to me. Wade

-

Well I hope so anyway;-) I should have known better in the first place. My mind sometimes does tricks on me. In any case thank you for your comments, not only to me but for your great contributions to this community. Wade

-

Linda, I think somewhere in another thread I saw your link to a gear calculator and I just wanted to say thank you. That is pretty cool. I think the 1985 6 bolt was also pretty short. I read somewhere that it is only 3.9 That makes sense to me and would be in the ballpark with all of the numbers. In any case I'm sure not going to 90 but I also have no problem holding it around 60 in 3rd on a grade to maintain speed. Wade

-

LOL! Actually, in her case, it was mechanical damage from the washing machine that posed a more serious risk to those ridiculously expensive undergarments. Thankfully a reduction eliminated the need for the heavy duty ones but I am sure she doesn't use bleach even though she no longer hand washes them. I was the one that hated what bleach did to my tighty whites. Everything that I looked at while working on the system looked much more like the bleach bottle than an elastic band so I really didn't think it would be an issue. Guess time will tell. All I know is that at the moment: A: The pump screen cleaned up very well and appears structurally sound. B: The 4 chambers, diaphragms, and 0-rings all look solid, didn't deteriorate when I scrubbed them, and are currently water tight. C: The pump is much quieter now and has very good flow. Time will tell if I did any serious damage. Hope not. Wade

-

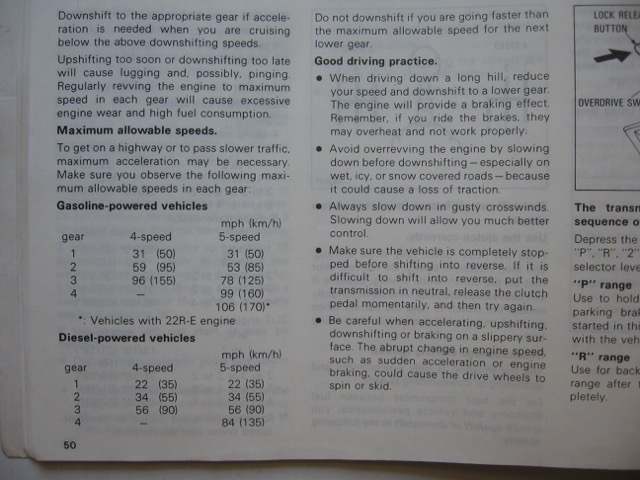

Linda, After my brain misfire on the Chlorine concentration, I had to double check to make sure I remembered correctly;-) I did and I don't think my engine would ever have enough power to reach that speed. However, if it were going down a big enough hill, according to Toyota, it could go that fast without exceeding the max RPMs. I was going to get a tach until I actually read the owners manual. My ear and common sense are plenty adequate. Red line is way beyond where I would go even if I could. Also, I am pretty sure if I were to ever put it on a dyno, the curve would drop noticeably before red line and I already feel that and shift accordingly. Perhaps Coachman is a bit more slippery than others. I know that I am plenty high and have a rooftop A/C but I am nearly certain that I am not using close to 95 HP at 65 mph. That would be very near all it has and it just doesn't take that much pedal to keep it there. I actually find myself setting the cruise at 59 because it is too easy to get up around 65 without sticking my foot way deep into it. OTOH, perhaps my speedo is off 5mph or so? Perhaps 65 is really 60? Yes I am talking about a 4 speed MANUAL transmission. No torque converter involved. Here is the actual owners manual. Read the chart for yourself and let me know if I am seeing cross eyed or something.

-

Yes, it was way too much. Pretty sure that is what caused the pump to "fail". There was a lot of gunk in the system and the bleach loosened it up. Don't think there will be any long term damage as I don't think chlorine is particularly harmful to the plastic and rubber parts that make up the system. What I know it does is remove things that are stuck on. Amazing what a solution of chlorine will do to clean up a glass jar that has beer making residue stuck to the sides. Simply amazing. I did get way carried away with the concentration though. Wade

-

Post shakedown update: The good: Full of water, LP, a weekends worth of gear and my wife and I, it ran smooth and cool. Frankly I am impressed at how much power it has. I put in a new factory OEM thermostat as my gauge was running a little below the middle. It is still there and after a solid run and the gauge not moving even going up a solid grade, my IR gun showed the hotest part or the cooling system at 210 and most of it in the 180 -190 range. Coolant was right where I put it in the tank on initial setup when I checked it after the big hills. Drops a little when it is cold. Basically, for most of the driving I will be doing, power will not be an issue. I wanted to take the shakedown through hills that I remember having to downshift on in my new 1984 or 85 company truck (F150 with a 300 six). That was the only time I had to go into 3rd going up a hill. Frankly I think I could have made one of them if I would have hit it doing 65. I am certainly comfortable doing 55 or 60 going up a hill in 3rd if I need to. Typically shift a bit lower than that unless trying to get onto the freeway but given that the owners manual says I can go something like 90 in third it just isn't an issue to me. FWIW, I parked it on a closed elevator scale and looking through the window I am pretty sure I saw 5560 with my wife in the truck and I won't tell you what I saw with her out of it;-) My acceptance of the power might be because we are a bit on the light side for these things and we certainly have more that we will load up. I also will be doing a certified scale one of these days to get axle weights. However, it looks like we will be right about at the listed max going down the road. Probably not too much over as many are. Coach power was great. Had enough to run a fan with my inverter as well as a powered speaker and recharge my laptop. Battery charged fine on trip home. Water was great with the freshly cleaned pump. The marginal: Body roll in the wind. Not really bad but definitely can keep you on your toes. I can see myself doing some suspension upgrades after everything else gets fixed they way I want it. There are those here who would say I run way to high of PSI on my tires and I may go lower and see if that makes a difference. Right now I am running 60PSI in the duals and 50 up front. The tires are running nice and cool and consistent as they are. The bad: Thought the problem with my gas tank was the return hose. When putting gas in, when the pump nozzle kicks off, gas drips out from underneath and I can't see exactly where from. Replaced the hose with a hole in it and it still drips after cut off. Am hoping it is just the big filler hose connection as while I can't see it, it doesn't feel quite right just past the clamp. The gas gauge has also quit working. So, I can't fill up and I don't have a gauge. Not good! No idea what my MPG is but have been assuming 15 and it appears to be better than that or I probably would have been in trouble by now. Can't wait to get that fixed for obvious reasons as well as the fact that I want to see what I am really getting. The ugly: The last leg of my trip was going into the Minneapolis St Paul metro on the freeway in heavy traffic. At one point I found myself going 70 MPH and it really didn't bother me a bit. I don't need to go that fast and don't want to burn the gas. Didn't think it would be something that the little Toy would even be able to do without feeling like it was going to fly apart. Apparently it will do it just fine;-) Wade

-

WOW! that is one sad story! While I am sorry that you went through it, I am grateful that you shared your experience. Reminds me that I definitely should go through the alternator before going far away from home. As for the water pump that was part of the rebuild 2k miles ago. Hopefully would have failed by now.

-

Mark, First I started with brake parts cleaner. Went through a can and figured I would need at least 3 or 4 more cans to clean it. In hind sight I probably should have used the scotch brite with the brake parts cleaner and I might have got in in one or perhaps two cans. Probably the best answer would have been to take it to a car wash. However, I wanted to have it on the road faster than I would have been comfortable with having the area under the top dried out. I ended up getting a can of engine degreaser from O'Rielys and using that with a scotch brite pad. Nasty stuff. I miss the old days when you could get parts cleaner and a brush but apparently those chemicals were even worse or the new ones just found a different loop hole. Who knows. I am happy that I now have a leak free engine and it is clean enough so that I should see it right away if anything starts to leak. It will also be nice as I know the cover will be off more than "normal" as I have no idea what kind of valve seats the rebuilders that O'Reily used installed. I know that I adjusted 3 valves when I was doing that project and there is only 2k on the engine. Will definitely check again in the fall to see if it was just sloppy workmanship or if the seats are working in. Wade

-

Exactly! On that note, my wife wanted to replace the fire extinguisher mounted right above the range next to the door on the wall. She got a new one and I went to put it back in the mount and thankfully it did not fit. I think it is a pretty typical thing to have these metal cylinders mounted on the wall of our coaches. I looked at that mount it it occurs to me that this is probably a pretty crazy idea. Those flimsy mounts are sure not going to hold that thing on the wall and what a projectile it is! Wade

-

Just a write up to hopefully help someone in the future. I think this is a fairly typical possibility. Bottom line, before replacing pump take it apart and check it out. My toy had sat for at least 3 years and the PO said he didn't think the pump worked. Hooked it up to city water and got a fair amount of trash out of the lines. Next, I put some water in and started the pump. It worked! I wouldn't say it was great but it was a working pump and I was happy. Next I wanted to see if I had any water tank leaks so I filled the water to full, emptied the sewer of what I had put in and then started to pump out the water tank to see if the sewer is OK. Pumped about 3/4 or so of the water to the sewer and drove it around town a bit. Much smoother and quieter in the back with all that weight shifted to the very rear;-) Everything was looking good so my next step was to dump a half gallon on bleach in my 1/4 or less tank of water and drove it a little bit then let it sit for about a day. Now I wanted to see if the sewer would take all of the water. Ran the pump until the tank was just about dry and the indicator said the sewer was totally full. Everything fine. Kept going until the pump would not pump any more water and that was just a touch too much for the sewer as it started to drip. Not certain when I am going to deal with that as I don't think we will ever push it that far. Next I emptied the sewer and re-filled the fresh water tank. Went to run the pump to rinse the chlorine out and I could hardly get a trickle of water. I could turn off the faucets and the pump would shut off after maybe 10 or 15 seconds. Not normal at all. Tried several times and I could never get more than a trickle out once the initial pressure was relieved. Now I have a full tank of water and can't get anything to pump. Went to pull the drain and nothing came out. Drain is downstream of pump. However, with pump running I could get a pencil lead stream of water out the drain. Ran pump for maybe an hour and a half and finally got the tank empty. My pump is a flojet Quad II 4406 series. Should have a separate strainer on the inlet line but mine does not. Perhaps one day I will put one on. However, there was a plastic mesh screen inside the pump on the inlet. This strainer is not shown on the parts diagram but it was clearly clogged with slime and it was clearly designed to strain the water going into the pumping chamber. So I cleaned everything up, inspected everything, it all looked good so I put it back together, plumbed it back in, put a few gallons of water in and nothing. Now things were even worse. Couldn't get the pump to even prime itself. Took it apart again, looked it over again, put it back together again, and turned it on. Didn't think I was getting enough suction but wanted to think it must might work anyway (willful ignorance at it's best;-) Not sure why I plumbed it back in at this point and you can guess the outcome. Everything looked good so this time I very carefully took it apart and simply moved the diaphragm 90 degrees. This time when I turned it on I definitely got good suction! Plumbed it back in and now I have excellent flow and a much quieter pump. The moral I choose to take from this story is this: A. Crud will get in your system and a thorough cleaning and flushing will likely dislodge it. B. If crud is restricting the water flow, the pump gets noisier and clearly the flow suffers. C. Cleaning the pump chamber / strainer to re-establish the water flow is worth about $100 for a new pump which would have done the same thing in my case as there was no other strainer. Time well spent. D. Don't just rely on a marginal parts diagram you downloaded from the internet. Pay close attention to how the parts came out;-) Wade

-

Finally ready for the shake down cruise! Still way too much to do but I want to put some miles on it and make sure that things will be OK. So far I have changed out nearly every hose on the engine. Below are the before and after pics. Hope to go to the bluffs of the Mississippi and perhaps Lake Pepin. Have had it up and down the Mississippi valley a few times as I live right next to it in Minneapolis and have taken the Toy to St Paul a number of times;-) So this was probably a crazy thing to undertake. Especially as the second project (tires, brakes and wheel bearings first). However, when I read through the thread about what some of you carry for tools (Love the welder story!) I am hoping to avoid the need for tools. Can't wait to update on the trip. Will be interesting to see how it does loaded. I am more than happy with the performance empty. Have a great 4th everyone! Wade

-

Did you happen to drive by this place on your way to your camp site? Last time I was up that way I found this place just in the nick of time. Was running on vapors and it is quite a ways till the next station. Beautiful country!

-

Seriously? As has already pointed out, doing POR 15 is anything but non-toxic. Here is the msds for FF http://www.fluid-film.com/downloads/SDS_NAS.pdf Here is the msds for motor oil. http://www.apauto.com/SDS Branded/Motor Oil/Shell RotellaT/ROTL 154055CJ4.pdf They are both petroleum distillate products that are listed as non-toxic. I already said that I am not planning to use used motor oil. As a matter of fact, I recently purchased custom machined billets for the head of my 22RE to eliminate the persistent leaks from the valve cover / head junctions. In addition to that, I am replacing all fittings on the valve cover as well as the entire PCV system hoses and valve. My guess is that my Toy will be somewhat less toxic than most. Wade

-

Since I now live in the city I was planning on laying out some plastic and using new oil vs used;-) Should be able to catch everything and be reasonably kosher. I remember in college I worked in farm service and got a metal tool box. Didn't take very long of using it in silos for it to rust out at the hinge. Soaked it in oil and the rust stopped. Looked terrible rusted but held for years whereas it was going to self-destruct in a matter of months before I put the oil on it. I like the idea of the POR15 but recognize my limitation of time and access. Would be more work than I would be willing to do to have it done right. Hopefully the oil will get me the same benefit without as much work. According to the coachbuilder I am supposed to go under it every 90 days and look for any rust or corrosion and fix any that is found. Too bad no one did that! This rig spent most of its life in NY or CT so there is rust but thankfully it does not appear to be too bad. There is a little spot on the windshield that I will likely use one of the paint based products on and the worst is on part of the dash. Not sure how I am going to deal with that. Wade

-

I am pretty sure it is the right relay. Looks just like the one I had on my old Dodge that I used to have to replace every few years;-) The voltages id do as you said IIRC. Will test again when I clean up the terminals. Thanks for the info and links! Don't think I have a CB installed so that might be a good idea. Wade

-

Jim, Interesting suggestion. I was planning on hitting mine with a mix of motor oil and marvel mystery oil but may also do the lamp oil thing. Can't stand the smell of kerosene. Reason for going with Fluid Film vs the simple oil mix? The rust thing is on my list but still way to many things to get done first;-) Wade

-

D'oh... Of course that is the correct procedure. I think what happened in my little test, due to the fact that zero was the recorded voltage on the other side with the truck battery disconnected, tells me that it is working to isolate. Now I just have to pull the other one off, apply power, and confirm that it is locking in. Thanks for stating it so clearly! Wade

-

Can anyone explain this to me? I took my ohm meter to my isolation relay and, with no power connected to the relay circuit, there was zero ohms resistance. It would appear to me that the batteries are not isolated. However, my starting battery was somewhat discharged and at a lower voltage than the coach battery. If I measured voltage to ground on the starting side it was a lower voltage than on the coach side. Both readings were close to the actual readings of the battery. I then pulled the starting battery and put in on a charger for a bit as I was making a wire to run the relay. While the starting battery was removed, I got no volts on the starting side and the correct voltage on the coach side. Got power to the relay and put the starting battery back in. Makes a significant clunk when power applied. Voltage equals (or at least closer to equal) on each side when engine is running. How is it that I can have zero ohms between the battery terminals on the isolation relay yet have different voltages, even zero volts when one battery is removed? Thanks! Wade

-

Jim, I get that. However, I am reasonably certain that the Toyota engineers who came up with the PSI ratings did not run their calcs with a Cube that extends 21 feet and is over 8 feet high attached to the chassis. The torsional load that such a huge cube must excerpt on the tires is likely significant. Wind, cornering, and braking, would tend to have the effects on the sidewalls amplified by the shear size of that cube compared to the overwhelming production of trucks that the calcs were likely based on. Likely the coachmakers just pulled the numbers out of a hat because they knew that what they were doing was going to have an effect beyond what Toyota originally designed for. Wade

-

I guess the mpg thing is kind of an ego thing for me;-) I like to have the engine and drive train as tip top as I can. On the deflated ego front, the mpg of the Toyota over the mpg on my old Dodge should mean the ability to use it for more or longer trips. Unfortunately there are too many times where I just don't have the $ to absorb the lower mpg. I just noticed the door sticker from the coach manufacturer and they spec all tires, single in front and dual in back, at 65psi cold. Wasn't expecting to see that. Wade

-

I can't speak for anyone else but for me, I do respect Toyota engineering. However, there are a multitude of reasons that I choose to run a higher pressure than what was in my owners manual. For one thing, there is little likelihood that an engineer in 1985 would have the data to recommend the ideal pressure for a tire manufactured in 2015. Tires have changed a lot in 30 years! I am glad that you brought this whole tread up Jim. I will do more experimenting and will likely run a bit lower than I would have before. Currently the tire shop set my tires to sidewall max. I am pretty satisfied with the way the truck handles but as this is my first Toyota MH, my expectations may be way off and it will be interesting to see how things change as I make different adjustments and hopefully some day actually have it loaded for a boondocking trip;-) One thing that I know I will do is monitor the tires with my IR gun. As it sits now, nearly empty with tires at the max, a 20 min 60mph run followed by a couple of miles of city streets to get to my house, resulted in even temps across all tires and just a few degrees above ambient. My owners manual states that the fronts should be in the 20s. If I ever were to drop that low it would be interesting to see how much additional heat would be generated. I am definitely going to lower them significantly from where they are now and see what happens. I also hope to take gas mileage into account. Unfortunately that is one more of my many projects to complete. I was going to fill the tank so I could check mpg when the pump kicked off on over-flow there was gas dripping from below. The tank is all covered in sheet metal so I don't know if it is a return hose or a leak in the tank. I do know that when I got home the leaking has stopped and I have about 3/4 of a tank on the gauge. Don't have a clue as to how accurate the gauge is. I do know that with highly inflated tires I am amazed at what my gas mileage appears to be anyway. The gauge was flat on E when I put 5 gal in. Drove it for about 50 miles mixed city highway and gauge was still more than an eighth. Put another 5 gal in it and drove it about another 30 miles or so and about 6.5 gal cause the shut off and left me with 3/4 of a tank. Wade

-

Should my chassis battery charge on shore power?

Wade replied to Rocinante Sunrader 88's topic in Electrical

Newbee question? Given the number of Honda dissing posts, is this supposed to be sarcastic? Not sure of the differences between different battery chemistries but if the description is accurate could be a valid point for the crazy $. For LiOn and LiPO batteries at least charging profiles are critical and common cheap chargers are anything but cheap! Wade -

Shore Power Works All, Battery Only Doesn't Work Anything

Wade replied to Jake_Womack's topic in Electrical

Having the same issue. Thanks for the info on the converter and micro switch. Will have to check that out tomorrow. Can someone explain this to me? I also have no coach power unless plugged in. However, I didn't have a battery until tonight. The picture below is right behind the battery. The lower terminal is the positive on the battery. Have not had time to trace the upper terminal yet. I know the lower terminal has 12V to ground and that the battery has the same. I would think that the upper terminal should be continuous with the lower terminal. However, when I put my Ohm meter across the two terminal it flashes between open and some random value. Would expect it to just stay open if that were a fusable link and it were blown. (It does not look deformed at all.) Actually I expected to see zero ohms across it. What the heck is that thing? Also, when on shore power, I would expect the battery to be charging. All coach functions work. However, the battery is at 12.57 which is about what I measured before I installed it. (New deep cycle marine battery that probably should be topped off.) Expected to see somewhat higher voltage to indicate it was taking a charge. My converter looks a lot like the pictures although I haven't looked at the specific model number. Not sure if this is relevant but the coach was originally equipped with a generator. The battery terminal in the generator box is just taped over and I did not test that for voltage and not sure what should be done with that now that there is no generator. Bunch of low voltage wires also in there going into a female terminal with the wire going back into the coach to run the start switch and hour meter. Thanks for your help! Wade