fred heath

Toyota Advanced Member-

Posts

2,039 -

Joined

-

Last visited

Content Type

Events

Profiles

Forums

Gallery

Everything posted by fred heath

-

https://www.facebook.com/marketplace/item/2014647928876884/?mibextid=dXMIcH

-

Did you check under the hood? Many times the coach battery is located there.

-

Lots of companies online. You’re looking at about $1.50-$2.00 per mile on average for a long haul. If it’s roadworthy, it might be more economical to hire someone to drive it for you. With the cost of fuel today it might be even more expensive.

-

May, 2023 Beginning '82 Sunrader renovation

fred heath replied to IdahoDoug's topic in General Discussion

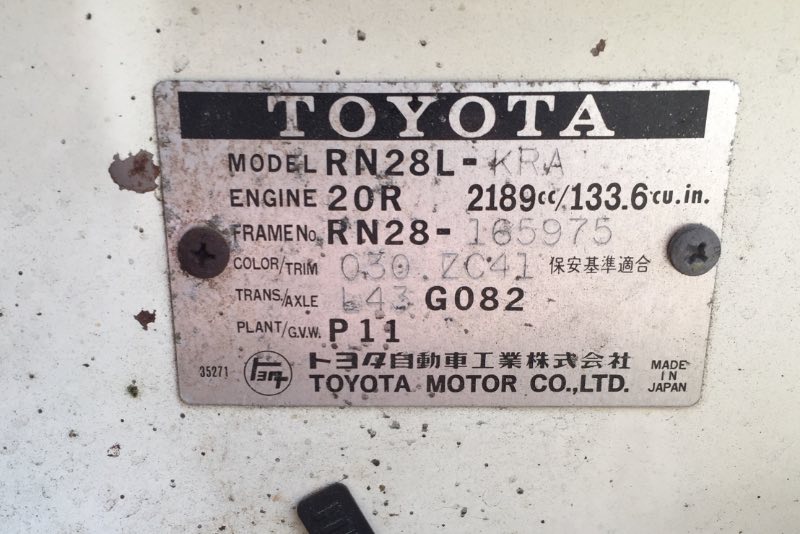

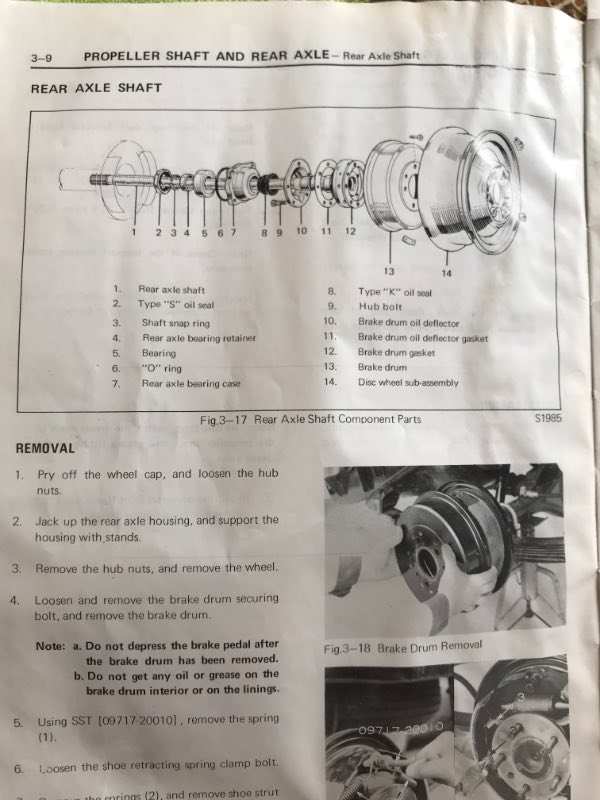

I’m pretty sure the GO82 and the F292 (71/2” r&p) are interchangeable. It’s been years since I’ve done this work so don’t quote me. Plug in your year of manufacture and see what shows up. The early cab and chassis were known as special purpose vehicles. If only one listing shows up, go with that. If you have a local Toyota dealer their parts department can find the correct number using your VIN or chassis identification. You don’t need to buy from them, just get the correct part number. I might be putting the cart ahead of the horse. I’m assuming you have the GO82 axle. That’s what most of the motorhomes use. Check for a metal ID plate usually attached to the drivers side inner fender or firewall. I’ve attached mine so you know what to look for. Also added some axle info from my FSM. Mine’s a 1978 but assembly should be the same. -

May, 2023 Beginning '82 Sunrader renovation

fred heath replied to IdahoDoug's topic in General Discussion

I always use a shop press. Keeping everything equal all around makes for a smooth removal and installation. You can pull your shafts, buy new bearings and seals then take to someone with a press to have the old pressed off and the new pressed on. Don’t forget about that snap ring….. New bearing assemblies are over $100 each side. Not something you want to take a chance with. -

May, 2023 Beginning '82 Sunrader renovation

fred heath replied to IdahoDoug's topic in General Discussion

The bearing body is the weakest link in the failure chain. The rollers weaken from the flex allowing even more flex to occur. Changing the wheel bearing is a good first step if you intend to continue use of the axle. A new bearing won’t correct any fatigue issues with the shaft, but will give it much better support. TheGO82 axle shafts are not available anywhere. You break a shaft, your axle is done. -

May, 2023 Beginning '82 Sunrader renovation

fred heath replied to IdahoDoug's topic in General Discussion

When you go to press the old bearing off the axle shaft be sure to remove the small snap ring on the shaft just inboard of the bearing. Easy to miss when covered with old grease. Very difficult to replace if damaged. -

May, 2023 Beginning '82 Sunrader renovation

fred heath replied to IdahoDoug's topic in General Discussion

I’m running 15” white wagon wheels with Thunderer 402’s in size 195/70R15. Added some inexpensive abs wheel covers to match the front 14” to the back 15”. Your wheel is a standard 5x4.5 bolt pattern. Plenty of aftermarket wheels to choose from. Your rear wheel bearings cannot be repacked. New bearings and seals will be needed. -

Two thoughts. 1. Axle shifted. 2. one spring installed in reverse.

-

-

Different shops charge different labor rates. Most shops will provide an estimate before any work is done. The national average for ASE mechanic’s is about $95 per hour flat rate for labor. If you can find a shop that works on big trucks, that might help. Their lifts can easily accommodate your rig.

-

Most rooftop a/c use a total of three capacitors. Start, run and fan. On a 39 year old unit I would replace all three. That’s what I did with my Coleman. You can also add a hard start kit at the same time. You don’t need to buy factory parts. Capacitors are universal in design. Copy the part numbers of your existing capacitors and order new through someplace like Grainger or even Amazon. Take lots of pictures of how the wires come together BEFORE unplugging anything. I replaced all 3 of mine for about $100.

-

Passive Auxilliary Hot Water Heater Assist??

fred heath replied to Bob the Builder's topic in General Discussion

I saw a rig a long time ago that had several copper heater cores connected in series on the roof. Owner painted them flat black. Not sure what was used to circulate the water, but he seemed very happy with this setup. -

Depends on what size wheels you’re running. Factory wheels are 14”. Someone may have changed them to 15” which is what your tire dealer is suggesting. Or he might be reading what his books tell him. The tire diameter should be no more than 27”. You need to be sure the tires will fit into the wheel wells without rubbing or bottoming out. I have 15” rims and am running Thunderer R402 in 195/70R15 size. The “70” profile is the better choice for me because I’m running single tires in the back. The original factory tires 185/14 were 25.75 inches in diameter.

-

Any other "Galavan" Owners out there?

fred heath replied to fred heath's topic in General Discussion

Yours makes 3 now that I have confirmed. One is on a Datsun chassis. There is supposed to be another one in Texas. Haven’t had a chance to verify that. Yours is a 1978 due to the porthole windows in the back. 1978 and 1979 are the only two years they were built. Any specific’s on the coach I can answer. Hopefully, you have the 6 lug rear axle and not the 5 lug. Welcome to our forum. -

-

79 Datsun Sunline camper - Similar to Toyota

fred heath replied to EVPowers's topic in General Discussion

The chassis is either a 620 or 720 Datsun pickup. Any do it yourself repair manual (Chiltons/Haynes) for 1979 model year should have instructions for tank removal. Also good to have around for other repairs. Think of your rig as a Datsun pickup with a camper attached. Makes ordering mechanical parts much easier. -

Just a guess, (a picture would help) but if the two wires going to the black piece are from the negative terminal of the coach battery try cleaning that contact area. Actually, clean all the contacts where two wires meet regardless of which battery post they originate from. Generators require a heavy gage ground wire to start efficiently. On my Onan 2800 the generator ground is attached directly to the coach negative terminal. Somewhere you got a bad contact. Clean everything you can find. Hopefully this will help.

-

Check your coach battery ground carefully. If everything was fine until the battery change, double check your connections. A bad ground will cause this condition.

-

Do you have duel rear wheels?. If yes, do they have 5 lug nuts or 6 lug nuts on the rear axle? If only 5 lug nuts, the axle is unsafe. This should be your first concern before any suspension work being done. If 6 lug nuts you’re good. Most shops that service trucks can accommodate your toy home on their lifts.