-

Posts

139 -

Joined

-

Last visited

Content Type

Events

Profiles

Forums

Gallery

Everything posted by mpanzar

-

regarding the threading. do you know what type of threads are on that brass fitting? I believe the fuel lines are similar to the brake lines and will require flare fittings. if the brass fitting is NPT it won't work for a couple of reasons. (1) NPT is not compatible with flared fittings (2)If the toyota end is not a flare type, it would be a likely be BSPT or R thread type which are also not compatible with NPT. If you the part to the auto parts store they can likely provide an adaptor fitting. In any case, i think the part you need is a metric female inverted flare fitting to adapt to hose.

-

@linda s I agree with both posts regarding two examples shown. and i agree with the principles you mentioned. Regarding the air deflector on the tractor trailers, that was designed and likely optimized over several iterations. As for our lovely sunraders, i am assuming they were not designed for aerodynamic performance, and if they were i doubt there was much testing and iteration. (if there is aerodynamic testing data with images, i think we need t-shirts made ). On our sunraders, the deflector like geometry just after the cabover section as you move towards the aft, may trip the flow (similar to the first truck image) due to the relatively sharp nature of the geometry as compared to the examples of the car and truck deflector. I'm not an expert in aerodynamics/gas flow or CFD but i have some design experience related to the subject and have encountered similar phenomenon due sharp geometry. Im not positive on the engineering, but i believe the sunraders deflector would cause boundary layer separation and promote turbulent flow. I guess there is only one way to find out!

-

With all due respect, the diagram of the car is not applicable to any toyota RV.

-

Passive Auxilliary Hot Water Heater Assist??

mpanzar replied to Bob the Builder's topic in General Discussion

Regarding the pump for the solar dome, if pumping to the roof and assuming the water will come back down to the pump level, head is reduced significantly. The caveat is that the pump must have enough power to overcome the initial lift or priming . Once the water is on the downhill side it will begin to pull vacuum and head loss will be reduced. I believe the pipe system is better than a tank system in this case. you'll have better baffling with a pipe system, the CG of the system/camper will be lower, and it should be less weight on the roof. My personal opinion is that the effort is not worth the heat output, id boil a pot of water and add it to some ambient temp water. -

Passive Auxilliary Hot Water Heater Assist??

mpanzar replied to Bob the Builder's topic in General Discussion

you could wrap a copper tubing around your exhaust for a cheap heat exchanger. -

1992 Toyota Daytona Selling Price help

mpanzar replied to WestCoastGuy's topic in General Discussion

Just a WAG to get the conversation going with some numbers, maybe $12,000.00 ±$2000 USD. -

ive driven both motors in motorshomes and box trucks, with auto transmissions, several years in each. i found the 3.0 much easier to drive, and quieter. Both motors had there problems at times, but nothing too serious, timing chain guide issues on the 22re and waterpump on the 3.0. In my opinion the 3.0 is not much harder to work on than the 22RE, but it is different. Most 3.0s on the road have had the head gasket issue fixed, but that is something to look out for.

-

Toyota Dolphin 1987 - Discontinued fuel gauge sending unit

mpanzar replied to Dario's topic in Fuel Tanks

This might help if your interested in installing a generic fuel sender unit. looks like the max resistance is 110Ω for a 4 runner -

those look like the self resetting fuses that have been bypassed. Those are all over my rig but wired to break the line leading to the house battery. in your case they look like they may have been used to distribute power along the main power line to the house battery. they served me well when my main power line was smashed/shorted between the frame and camper shell during a trip once.

- 8 replies

-

- power center

- battery

-

(and 3 more)

Tagged with:

-

New Proud Owner of a 1988 18ft Nissan Sunrader

mpanzar replied to lucidawake's topic in General Discussion

-

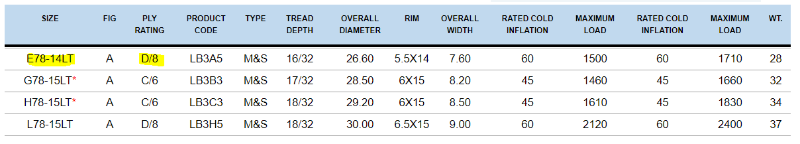

Im running STA Super Traxion tires on my rig. While they are not considered winter tires, they perform better than any tires i have used in the snow. Additionally they stop much better in the rain than any tire I have used. The down side is the road noise, but the improved handling is worth it to me. The specific tire is STA Super Traxion E78-14LT When the snow is fresh they plow right through with excellent traction, and have decent braking. I carry two sets of chains for when conditions get packed and icey, especially when going down mountains. lastly, one of my favorite winter sunrader tools are tire socks. They are worth their weight it gold. they are quick to install and usually get me out of trouble. depending on the conditions I use them to get to a better chain up spot if im going to be on snow for awhile. but most of the time they have enough traction and reliability to complete the task.

-

Ugh i feel your pain regarding the AFT fluid on both points... health and cost. I had a toyota box truck in the past that had a A43D. It needed a little work due to a hairline crack in the pan caused by rubbing a bent cross member. It was definitely abused as a uhaul truck, and run with low fluid for thousands of miles under my ownership. But it never stopped working, ran cool, and performed better and longer than i expected. If i remember correctly it had a pretty big filter and oil cooler on it. not sure if they were stock.

-

This sounds like a valve body issue to me. Could be a poorly seated gasket, or maybe even a missing part or seal since reverse not showing any signs of engagement. In my opinion, since the reverse is not engaging at all and the forward gears are always on, id pull the valve body, stone the faces to knock down any highspots and buy a new gasket, and filter(s) while you're in there. I would consult the manual for the torque and bolt order since the valve body gasket isolates so many small passages, similar to a head gasket.

-

I have an 86 and the lights turn on and off with my headlights. My rear running lights are wired in to the passenger side rear tail light. this is probably a good place to start checking the wiring.

-

i think im in love

-

Ive changed mine to polyurethane and did not have any issues installing them in on my 1986 sunrader. I was able to push them in by hand on both the original springs as well aftermarket springs. i used the same size bushings on the leaf spring front, as well as the rear shackle. I think i used these ones all around: Do the smaller bushings fit both sides of the spring? I remembering ordering extras of the small ones because of this.

-

following up with some more info: The 10s are currently installed without airbags. although i will install airbags again at some point. the 10s keep the rig a good height but its 50% gutted in the back so once i add everything back in im sure ill need them once im loaded up. regarding the bushings i have has the polyurethane type installed and i was able to inspect them when doing the swap. They looked good and have about 2 years of use on them. the ones in the rear seemed to have taken more of a beating compared to the front ones. Overall the rig is much nicer to drive with the new springs. paired with the beefed up torsion bars the rig feels very stable. and i agree with atlantacamper, ditch the rubber bushings, even if they are OEM, the load combine with rough roads destroy them very quickly.