-

Posts

41 -

Joined

-

Last visited

Content Type

Events

Profiles

Forums

Gallery

Everything posted by A Seabee

-

20r can't pull us up hill. Any tricks for a little more power?

A Seabee replied to Ifthis's topic in General Discussion

It probably wouldn't be too hard to swap a 22RE in. A good cam, fresh timing chain and a little head work should yield 150 or so HP -

how does the switch on the end of the shifter come apart?

-

I also use it almost always. My OD Off/on does not work though, so it helps the kick down when in the mountains. yeah, fuel economy sucks, but it sucks either way. just happy I have a little house on wheels

-

Ideally, a mechanic would measure the clearances, calculate the needed shims, remove both camshafts, and put it all back together with adjusted valves, new timing belt, cam seals, and a crank seal if needed. water pump and timing belt idler too if there's any sign of leakage out the weep hole and or the idler is noisy. You may end up spending $1000 if it needs everything, but you won't need to go back in like that for at least another 60K miles.

-

Is it still in the shop? The valve clearance can be checked with nothing more than a feeler gauge and the tools it takes to get the valve covers off. I've seen these engines go 160,000 miles without a valve adjustment needed. A solid mechanic could perform the adjustment if needed without any special tools either. But, if the shop doesn't have an assortment of shims, then the shim thickness needed will have to be calculated and then ordered. Exhaust valves are the ones that tighten up first. Another thing I'd ask for is to have them make the clearance at the big end of the range. the clearance if I remember correctly is .007-.011'' for intakes and 009-013" for exhaust. I'd have them get as close to .013" as they can without going over. On these engines, a noisy valve is a happy valve.

-

-

Not a mechanic anymore, but when I was, I worked at Toyota. I've probably rebuilt 100 3VZE engines. The rule of thumb was "it's never the computer" The roaring noise-check your fan clutch, maybe it's locked up the lack of power... you gotta check all the basics first. wet and dry compression test. valve clearance, air boots, air flow meter, timing belt, distributor base timing, plug wires (original?, arcing? ), fuel pressure Is the fuel filter plugged? is the fuel pump working? is there water in the fuel? does it have a blown head gasket? how many miles does the engine have? you can check for codes with a jumper wire in the DLC under the hood you can use the same jumper wire to power up the fuel pump

-

front and rear stabilizer bar bushings get dry, take apart and lube with copper anti seize. that's where I'd start

-

-

saw a rub through like that once on a 22RE pickup. the temp gauge read high. after replacing the radiator, thermostat, fan clutch, water pump, I found the wire harness that comes up and through the intake to the injectors and senders was rubbed through. the only wire affected was the one to the gauge sender. one strand of wire was making just enough contact with ground to make the gauge go high.

-

Food for thought to all of us... I worked on many Toyotas in the 10 years I wrenched there. Anytime I ever removed a fuel line, I would go back and loosen the gas cap. I don't know the physics of it, but if you leave the cap tight, fuel will leak out of the line you have off. Loosen the cap, and it can sit for a month with lines disconnected. I think the fuel expands and makes a slight pressure that pushes it out of the open line. With the cap loose, it just expands and contracts and any pressure just vents out the cap.

-

Terrible to lose a nice MH like that. I sent you a PM with a question

-

Come and get it Mirage Southern California

A Seabee replied to A Seabee's topic in General Discussion

No paperwork? it's got way more than $200 worth of good parts. I bet they'll pay someone to take it rather than deal with code enforcement. -

Found this on CL, https://inlandempire.craigslist.org/rvs/d/wildomar-1970s-toyota-mirage-come-get/6891407932.html

-

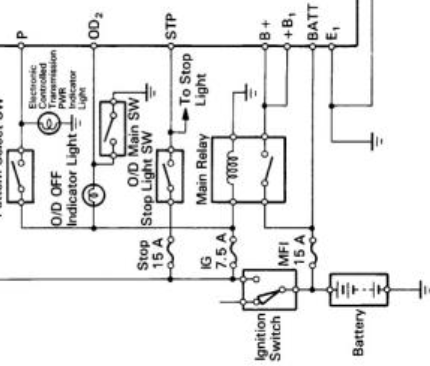

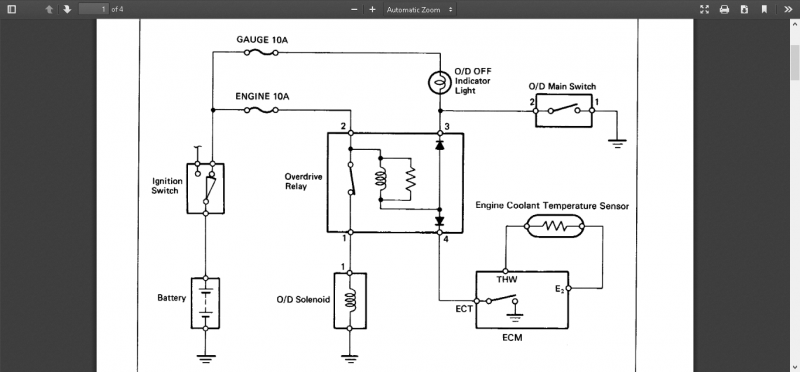

I tried to get codes from jumping the DLC, CEL blinks no codes, OD Off does not come on at all. Isn't the OD master switch an input to the ECM? how does the voltage get to the switch if the bulb is between the fuse and the switch? I can't imagine they would push power to the switch through the computer and have power coming from the ignition switch and fuse too. I do not have the factory wiring diagram, only the page that was posted here, and going by that, I can't see how the switch could work if the bulb was open. if you look at the pattern select switch in the diagram, if it were open, you'd lose your ground to the switch. no light, no ECT Power function, right? on the OD2 main switch, when you close the switch, you'd be grounding a circuit with no power leg if the bulb was open, no? and if the power came from both sides, how could grounding the wire before the bulb (OD2 side) make the light work under any circumstances? it would be a short to ground.

- 33 replies

-

- overdrive switch

- overdrive

-

(and 1 more)

Tagged with:

-

The OD off light never comes on. key on/button/jumped DLC. never. Am I reading the wiring diagram right? It looks to me like if the bulb were open, the OD switch would not get power...

- 33 replies

-

- overdrive switch

- overdrive

-

(and 1 more)

Tagged with:

-

I never took the instrument cluster apart to check the bulb, but I tried to make it work through the wires from the shifter. there's only 2, and I applied ground to both. but... it looks like from this diagram that if the bulb is out, the OD main switch will not get power

- 33 replies

-

- overdrive switch

- overdrive

-

(and 1 more)

Tagged with:

-

anyone here have a V6 with OD that works properly? Does the OD OFF light come on at key on before engine start up?

- 33 replies

-

- overdrive switch

- overdrive

-

(and 1 more)

Tagged with:

-

That's exactly what I was thinking, downhill will not be something I'm not looking forward to. gonna fix it before I go into any real mountain travels. thanks for the input! I'm pretty sure it is going into overdrive. the drop is about 350 rpm. I can also feel the lock up and see it on the tach, it is less of an rpm drop.

- 33 replies

-

- overdrive switch

- overdrive

-

(and 1 more)

Tagged with:

-

sorry all for the late reply, am out of town on work and coach is at home. Yes, it is a six cylinder, no, I have not accessed the bulb to see if it's good. I am positive that the overdrive is working...on the freeway at 55-60 mph, there's a distinct shift and RPMs drop to 1900.

- 33 replies

-

- overdrive switch

- overdrive

-

(and 1 more)

Tagged with:

-

well, the OD OFF light never comes on, even with the initial key on check. the diagram I posted is for a 4 cylinder A43D, not a A340E, which i think is the trans for the 3VZE. I took the plastic off and found a two wire connector coming directly from the shift lever. could not find the relay.

- 33 replies

-

- overdrive switch

- overdrive

-

(and 1 more)

Tagged with:

-

I will check that fuse, but the engine fuse must run more than just the OD. In any case, I don't think the OD OFF light is confusing, it just doesn't work. the button is not momentary...it has an on (in) and off (out) position. I have overdrive. the light and the control of turning overdrive OFF is what I don't have. So, grounding terminals 3 or 4 energizes the relay coil and opens the relay switch, and turns off the overdrive, right? then if that's the case, wouldn't an open circuit at 2 (blown engine fuse) cause the OD NOT to work? I'm just saying, it looks to me like the schematic shows a normally closed relay contact (1&2) makes a complete circuit to run the solenoid. anything that opens that circuit, fuse, or grounding relay terms 3 or 4, would make the OD turn off. I'm thinking if I ground 3 on the relay, I will get my light back and be able to shut it off again. gonna go try that. Thank you all for the input. If that works, I will buy the shifter that's up on Ebay.

- 33 replies

-

- overdrive switch

- overdrive

-

(and 1 more)

Tagged with:

-

Thank you, I will probably buy that one. is the OD OFF light supposed to come on when you turn the key ON? would a broken wire at the switch make the light never come on?

- 33 replies

-

- overdrive switch

- overdrive

-

(and 1 more)

Tagged with: