REALLYRURAL

Toyota Advanced Member-

Posts

100 -

Joined

-

Last visited

About REALLYRURAL

Previous Fields

-

My Toyota Motorhome

1988 Toyota Itasca rebuilt in 2012 rewired 2014

1991 Toyota Warrior currently undergoing full restoration. Had a pine tree fall upon it. -

Location

Located in Midcoast Maine

Located in Downeast Maine

Located in Central Florida

Located In Rhode Island

Profile Information

-

Gender

Male

-

Interests

Traveling. Well paying work that pays for the traveling.

Small motorcycles that fit inside the Toyhome and riding them.

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

REALLYRURAL's Achievements

Explorer (4/14)

-

Rare

-

Rare

-

Rare

-

-

Recent Badges

-

Sorry, about being remiss in finishing a story that I started. To make amends I will review my notes and post as the story makes sense. The outline of the trip is that I left central Florida picked up I 75 and hit 81 to head north. That route was great. I made a few side trips met some wonderful people and found that Loves truckstops are the place to fuel, stop, shop,and get some rest. The highways are in great shape until you get to Pennsylvania then everything is a shit show. However, the drive was so much more enjoyable than any experience on 95 has ever been and if one has a towed or motorcycle then one could spend months exploring. The most unpleasant part of the trip was getting through Atlanta. I do not believe it is possible to find a decent way around or through this area. It holds everyone hostage who gets anywhere near.

-

Most likely you have a problem in the wiring underneath or a bad ground. Crawl underneath and look at the wiring harness. Bring a test light and figure out which wire is which. Pretty common situation and the wiring needs maintenance on these rigs.

-

150 thousand miles on it. Drive it like you stole it. It did not get that far without someone giving it some love. Runs,drives smooth, shifts right, no roof leaks, stops well (well enough the front brakes on these rigs do most of the braking) and all the lights work. Make sure you have good brakes, new tires, a full coverage motorhome policy and go have as much fun as you possibly can with it. Change the fluids if you have time.

-

1992 Toyota Daytona Selling Price help

REALLYRURAL replied to WestCoastGuy's topic in General Discussion

The layout of your rig really apeals to me having spent much of the last ten years living and working out of my ToyHomes. For the most part these rigs have no comfortable place to sit for extended periods. So having multiple places is the next best thing. Change where you sit and lay down so you do not get out of whack. So the layout of yours is really inviting. If you invite someone in they can sit in the chair or the settee on the pass side and you can be a host without having to move around the hosted. It is a good looking rig and set up well. -

1992 Toyota Daytona Selling Price help

REALLYRURAL replied to WestCoastGuy's topic in General Discussion

I received an insurance payout of 14,500.00 for my 91/92 Warrior in October 2022. Put the rig off the road for a brief trip through a stand of alders. Insurance declared it a total loss. I purchased the rig back for 4k from the insurance company. Full coverage motorhome policy from S t a te F a r m 220.00 per year. -

So been in Florida since mid January. Towed a trailor with the Yamaha Tw200 on it and have sinced picked up a Kawasaki KLR650. Planning to head up I75 to check out the Smokies and some of the great motorcyle rides there. Leaving on the 22nd and wanting to hit the area on Monday so that I do not have to compete with the weekend warriors at Deals Gap. Just put new tires on the 91 and ckecked all the fluids. It should be interesting taking the Toyhome through the mountains with a trailor with two motorcycles on it. So far on my trip the RV has got as alway 10 mpg no matter what. The KLR gets 45 mpg. Anyone been up through those areas this time of year? Hope To See You On The Road.

-

Been in Umatilla (30 miles north of Orlando) since Mid January. I have seen several Toyhomes around here. Have spotted a Sunrader in Leesburg around 441 several times. The A340 is a tough transmission no need to do without the overdrive.

-

I just purchased new Hancook Vantras for the front. Tire Rack 303.86 for two. I replace the 4 rears in January 2021. The pair that were replaced I had put 10,000 miles on them. They came with the rv and had a date code of 2217. Twenty second week of 17. They were showing some cracking in the center of tread and my alignment is off and it wore the outside on both tires (might be caused by loosing the airbags). If it was not for the alighment problem the tires would have over 50 percent tread. I would be replacing them at this point anyway as they were six years old, showing some cracking and about to put two to three thousand miles on in the next few weeks. I like the Vantras been using them on two different rvs with great results Buying them from Tire Rack they come with free roadside assitance and a two year warranty. That is a nice added bonus to the tires and a bit of peace of mind on a long trip. https://www.tirerack.com/content/tirerack/desktop/en/tires/trhp.html The nuts on my valve stems where just about corroded away (you might want to check on that). You can get the correct stems here: https://www.toyotapartsdeal.com/oem/toyota~valve~for~tubeless~tire~90942-05026.html?vin=&make=Toyota&model=Pickup&year=1990&submodel=2 Wheel Drive&extra1=&extra2=&filter=(d=USA;1=3VZE;4=STD;7=RCB;8=WT;9=HLF;11=EFI;13=IV6;14=T1) The part number is correct so you can call a toyota dealer and they can get them. Dealer in Leesburg Florida said they where 5 days out and 22 bucks apiece. I did find that the stem hole on my spare tire had been drilled out so I had to use a different stem.

-

I rebuilt my 1988 toyhome overhead with thin tongue and groove cedar from home depot and glued it with 3m 5200. It was a relatively easy rebuild and I stopped and enjoyed the rig for a few years before digging deeper.

-

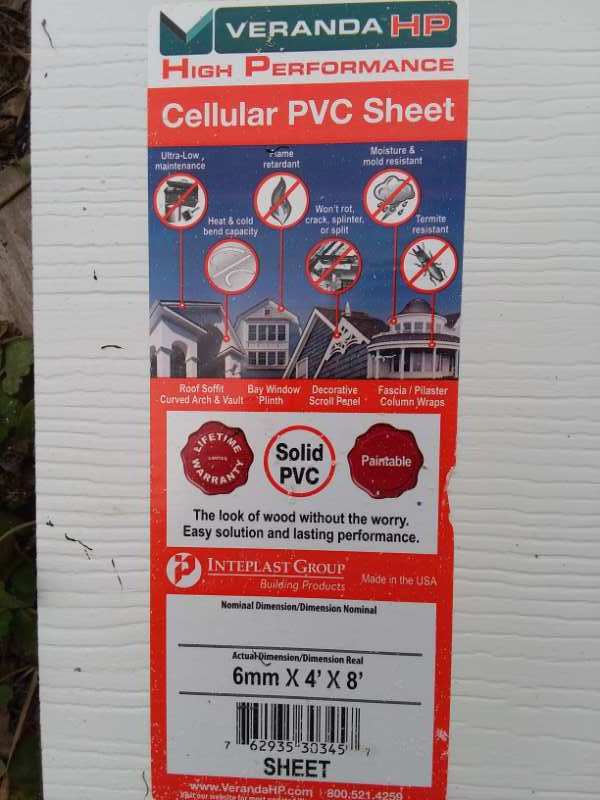

The pvc products I used on this project all come from home depot and Lowes. PVC now comes in 4x8 sheets 2x8 sheets of different dimensions. It also comes in 1x1 to 1x12 in many lenghts. To do the forward end of the cab overhead I used a FRP (fiberglass reinforced plastic) sheet that is normally used in bathroom walls or other wet locations. I made the bends very easy to do and has held up very well after 20 thousand miles. All the wood was replaced with pvc 1x whatever was needed. except for under the roof I used 5/4 pressure treated decking. The wood at the bottem of the skirts was replace with pvc and glue with a marine adhesive.

-

Well Upload a bunch of pictures of you rig.

-

I did purchase this rig for less than 10 sheets of plywood and the previous owner had dumped it at a salvage yard. I cannot purchase storage this size for less than 100 bucks a month. I am goiing to rebuild and put this rig back on the road. But seriously, awesome save! Out of curiosity does it have the evil bad axle?! Not starting the whole OMG its unsafe ordeal, just wondering lol. Ths rig has a full floating dana axle. The front end has failed torsion springs.

-

Who was the member you got rid of?