Boundfornowhere

Toyota Advanced Member-

Posts

57 -

Joined

-

Last visited

About Boundfornowhere

Previous Fields

-

My Toyota Motorhome

1985 Toyota Sunrader 4x4

-

Location

Traveling North America

Contact Methods

-

Website URL

boundfornowhere.com

Profile Information

-

Gender

Male

-

Interests

Hiking, Climbing, Surfing, Fishing

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Boundfornowhere's Achievements

Newbie (1/14)

-

El Rito started following Boundfornowhere

-

Unfortunately I don’t have the proof in photos. We weighed it at a weigh station in Oregon before the renovation and later on in Florida at a CAT scale. I’m wildly curious what it would have been as a shell. The 5,800lbs figure was dry but with almost all our gear. Safe to say it would be around 6,000lbs wet (I believe our water tank was less than 20 gallons). It still impresses me with how light these trucks are. Modern trucks are so much heavier. Our current vehicle is a Tundra with a flatbed four wheel camper and it’s close to 9,000lbs (wet and with gear). Thanks for the condolences for Luna. She is deeply missed. When we come back to Florida this winter I’d love to see the Odyssey!

-

Our Sunrader was 5,500 lbs before our build and was still under 5,800 lbs after (with all our stuff). Yeah, we still creep around on here 😉 On a separate note, I have been really enjoying this build and look forward to seeing it get all done. Lots of great information in here for people in the future. Haven’t seen a build this good since Matt’s Sunrader (Yotahome4x4) who is now making the Truckhouse that Linda referenced up there. Thanks for sharing al your hard work!

-

Damien started following Boundfornowhere

-

We used Pettit EZPoxy paint and primer for the body and Raptor Liner for the fenders and ladder. Details on the process and links to products can be found on our blog. Links to paint and primer can be found at the bottom of this post that details our painting process: https://www.boundfornowhere.com/blog2/2017/build-out-week-8-9 Links to Raptor Liner and details on the process can be found in this post: https://www.boundfornowhere.com/blog2/2018/build-out-week-10

- 102 replies

-

I would love that! It was a definite bummer we couldn’t meet up back then. We’ll be up in your neck of the woods this spring so hopefully we can make that happen and we’ll have our new home on wheels too! The taco was a way for us to get back on the road while we looked for a more permanent solution. It was amazing and we truly love that truck. MAK worked on it almost full time for those 9 months which was the main reason we aren’t STILL working on it. As for MAK’s dad (ha, glad you asked. Unsung hero), he’s been keeping busy in the shop making cutting boards and knives. They also bought a new boat and he’s been able to dive deep into his passion for fishing with all this new free time.

- 102 replies

-

Thanks a ton for the offer and what a deal! All this axle stuff is way over my head and it still very much is. Seeing the helpful responses here I can’t help but wonder “what if”. I’m glad to know that there are more options out their for people rebuilding than we originally thought. All this info is super useful and I think I’ll be passing it on to the new owners too. They bought it knowing there was work to do on the handling and all this could be immensely helpful.

- 102 replies

-

The power system was absolutely perfect. That is what I miss the most about it (although I could be a bit biased). We were never wanting for power and I LOVED that battery monitor and how could look at everything from my phone. Water was also good. The water pump we got was so much more quiet than the one the Sunrader came with. In hindsight I would have gotten a smaller water tank because the one we got barely fit in that space and it made running the water lines a little bit of a hassle. The extra breathing room would have been nice. We did have front and rear sway bars. In hindsight I would have stayed dually. The most important thing for us was changing the axle. We didn't want to put all this work in just for it to fail. I guess that would mean sourcing an old full float but I don't recall if the gear ratio is the same. We talked to a few people that managed this conversion to single wheel without the handling issues we experienced. So in an alternate hindsight universe I would have tried to drive it somewhere that might have some experience with that type of stuff. No one in Orlando had any idea what I was talking about.

- 102 replies

-

So as you may or may not know, we did end up selling Amelia, our 4x4 Sunrader. It's a long story that begins with the infamous axle. We converted to the full float in order to have all the wheels keep the same bolt pattern so that we would only need to carry one spare. We also did this so that the gear ratio of the rear axle would be the same as the front for the sake of 4WD. When this swap happened things never quite felt right again. She was really tippy. We took her to a shop that specialized in suspensions for large vehicles and had new leaf springs, bushings, and shocks put in. They also said that adding a timbren could help as well. Once we got her back with the new suspension she was significantly better but it still wasn't what we were hoping for. After a lot of debate we ultimately decided that we would put her up for sale. It was not the ending we had hoped for but in the end we grew and learned so much from this that we have no regrets. Our final video on Amelia goes into this a little bit more. If you guys have any more questions about the build PLEASE don't hesitate to ask. We are an open book and we really want to help as much as we possibly can. Thank you for following along through the process and hopefully we'll see you out on the road.

- 102 replies

-

Now on to the final reveal! As I said up there, we're super proud of how it turned out (and frankly, that we finished it). It took way longer than we had hoped but good things take time. We'll start with the interior. Then on to the exterior! If you want to see more about it and hear MAK speak about the final product you can watch it here:

- 102 replies

-

You can also see the whole build in video format at our youtube channel. Here's a link to the whole playlist: https://www.youtube.com/playlist?list=PLp6o3lmSj5tQ5XS7u64OTcH2gR1RCjxa1

- 102 replies

-

For those interested in nerding out over the electrical system, I wrote an in depth post about it. It covers everything from solar panel to battery monitor. http://www.boundfornowhere.com/blog2/2018/its-electric I also cover a lot of the same stuff in video format here:

- 102 replies

-

After the water tank was installed I set out to get the water pump in. Success! MAK being the artist that she is, was tasked with painting the curtains. She had done research online and found a way to add what's called a "resist" to the fabric so that she could achieve perfect stripes but also have a hand painted feel. With the curtains done, things were really coming together. Next we moved into finishing off the drawers by adding faces to the front with latches to lock them into place. MAK and her father finished up the driver side counter. I ran the propane line to our stove from the regulator. We then worked on adding new sensors to our grey water tank, sensors to our new fresh water tank, and installing a panel to keep track of them. This panel also is the home of the power switch for the water pump. At this point we had a few areas of exposed fiberglass on the interior still. We had been dreading tackling these areas as they weren't super straight forward. Eventually we powered through with a lot of help from MAK's father. After the finishing work was done on those bits of the ceiling we moved into the home stretch. We added a pelican storage box on top, some sand ladders below, another bookshelf, and a housing for USB outlets. Last but not least, we had some decals made to rep the 4x4 and our blog.

- 102 replies

-

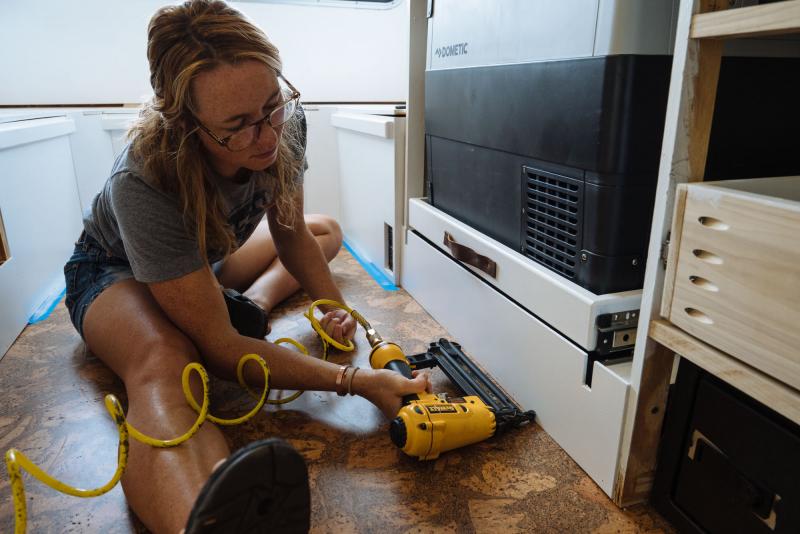

Before diving into the drawers, we make some small bookshelves for the back wall. Then it was all hands on deck for getting the drawers for the lower cabinets done. At this time we also installed the faucet. The fridge got 150lb over travel sliders. That way it could come all the way out of its space so that it would be easier to open it. That was a big job. There were lots of little details in everything. It was a huge relief to finally have those in. During that whole process MAK also finished the back table and we installed our water tank.

- 102 replies