-

Posts

2,186 -

Joined

-

Last visited

Content Type

Events

Profiles

Forums

Gallery

Everything posted by Gulfstream Greg

-

Great write up! I learned my lesson about not replacing those shoe retainer pins on a 1961 International 4x4 Scout. I was out in the middle of no-where when one of those pins wore through on a rear axle. Could not move without it locking up. Luckily found a large nail, stuck it in there, bent it over on the outside and secured it with a couple zip ties to the E-Brake cable. It got me home! Now if I see any wear it gets replaced.

-

I agree with Linda, If it is a true 1 ton chassis then all the brake parts are different from a 1/2 ton. This is not just a pull the drum off job. It is always best to have the drums turned or replaced. Having to bleed the brakes is always a pain but replacing the slave cylinders and flushing the system is highly advised. New shoes will compress those cylinders pushing the seals back into the housing that could have wear or corrosion issues. Seen it many times, new shoes and a cylinder starts leaking. Inspect all the parts for wear and replace if needed. Replace the axle seals and maybe the hub axle bearings. Look at the bearing races for bad signs like discoloration or itty bitty pits etc. At least clean and re-grease the bearings. I believe there is a gasket on the axle retainer plate. Find a good auto parts store that has parts listings for 1 ton chassis. Make sure the counter person understands you want 1 TON FLOATING AXLE PARTS. As others mentioned the proportioning valve is another story. Here is an article about doing the rear brakes, could be helpful. http://daysofexploration.blogspot.com/2013/04/third.html

-

Furnace Heater Trouble Shooting- Help Needed

Gulfstream Greg replied to Jules the Dolphin's topic in General Discussion

These furnaces have two fans, same motor but a fan on each end of the motor. One fan circulates the air inside the coach. The other fan circulates air inside the combustion chamber, it pulls fresh air in and exhaust gas out. The combustion chamber is supposed to be a sealed system to keep carbon monoxide out of the living space. It is also supposed to be debri free to prevent back pressure. I have no idea if that combustion chamber becomes pressurized or becomes a vacuum when that circulation fan is running. So If that burner gasket has become damaged it is possible for CO to enter the living space. So I say make sure you have a good operating CO detector! -

Furnace Heater Trouble Shooting- Help Needed

Gulfstream Greg replied to Jules the Dolphin's topic in General Discussion

Not sure if this is the correct manual 8516. Is there a window that you can see the spark wire? The porcelain that the spark wire runs through can sometimes crack allowing the spark to short to the chassis. Same with the wire. You will still hear the snap of the spark. Same thing for the high voltage coil on the board, that coil can go bad and you will still hear the snap. Electricity is like water, it takes the path of least resistance. The spark igniter wire probably sparks to the burner. A bad destroyed burner will cause the energy to go elsewhere, the path of least resistance. That said it is possible to kill the high voltage coil in that scenario due to internal arching. If your burner is good then try bending the wire closer to the burner and see if you get spark. Note that the spark wire also senses if the is flame after ignition. Long story but rule out everything before throwing a new board at it. Even check your electrical grounds. -

The important part is your refrigerator needs to be level when parked or it could be damaged.

-

The lug nuts should be final tightened with a torque wrench. Can't remember what that number is, maybe someone else knows.

-

Am I ready? Looking for any and all tips!

Gulfstream Greg replied to laurennn's topic in General Discussion

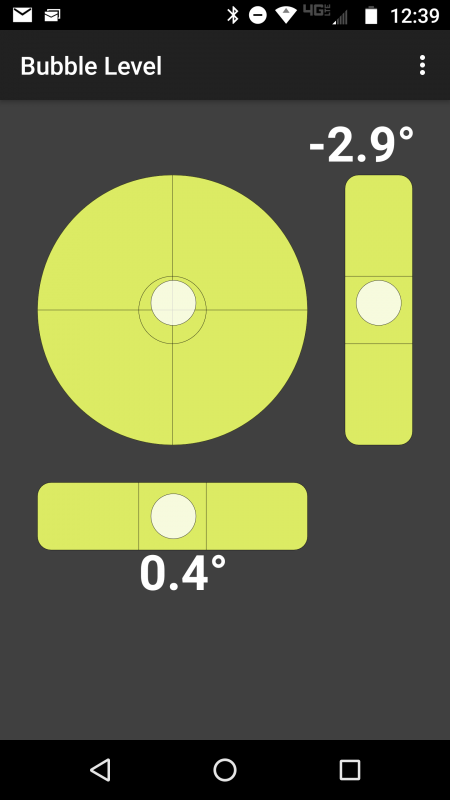

I have an app called "Army Knife" on my android phone with a level. I put a pencil under one edge to get the 3 degrees, not much on the bubble. App was not calibrated though for my phone case. -

Am I ready? Looking for any and all tips!

Gulfstream Greg replied to laurennn's topic in General Discussion

I like that! -

Am I ready? Looking for any and all tips!

Gulfstream Greg replied to laurennn's topic in General Discussion

That maybe true but how can you determine 3 degrees. Are there any levels that can tell you that, maybe a smart phone app? Some of these refers are as old as the hills and probably been tortured a bit during their lives and as a result have some solidification already. We replaced the refer in our last toy because unless you were dead on level it did not cool. But back to the 3 degrees, how far is the bubble out of the lines for 3 degrees? -

Am I ready? Looking for any and all tips!

Gulfstream Greg replied to laurennn's topic in General Discussion

What I do is start off by getting the freezer tray level with a small 6 inch level. Once that is level then find a surface outside the refer but near that is also level for checking when parking, the sweet spot. Stick on levels are good also. I had some in the cab but found that they were best used to get close then do the final leveling using the the sweet spot inside. When facing the refer left to right is more important than front to back. If possible find a level spot at your house or get the rig level and fire up the refer a day before you are going to leave. Get some empty soda bottles filled with water and freeze them in your home refer and place them in the rv refer when you start it. Cold thermal mass really helps these refers on start up. For easy leveling of your rig when traveling consider the lego style leveling blocks. Another item for that I find useful is a set of $10 floor mats from Walmart. Place a mat under the blocks when on hard surfaces and it will help prevent the blocks sliding when you attempt to pull up onto them. Note that when these refers die because they have been run not level there is no repair. Time for a new refer. Do a test run at home. Once you get it level start it up. Put some drops of water on the freezer tray. After awhile it should start to feel cold to the touch and eventually freeze the water drops. Also note that the older the refer is there is a possibility that the spiral baffle in the chimney degrades, rusts out. The baffle is part of the system that transfers the heat from the flame to the refers tubing. For electric there is a heating element that inserts into a metal tube that is attached to the refers tubing. That array also gets compromised with rust and does not conduct heat as well as it should. So you might find that gas cools better than electric. -

Am I ready? Looking for any and all tips!

Gulfstream Greg replied to laurennn's topic in General Discussion

Welcome aboard! You are spot on about the 4cyl transmissions. They do not have a locking torque converter so when in overdrive the torque converters slip and generate heat. You did not mention what rear axle you have?? And you know about your refrigerator needing to be level? Sounds like you have done some testing and know what the normal sounds should be. I like WME's idea about checking tire temps. Additionally a good pressure gauge is a needed tool. I also like the trucker thump test, a low tire will sound different. -

If the knob is just spinning around then the wires are probably twisted together and possibly shorted. Maybe I missed this in all the posts but has the column covers been pulled off, finding the wire and plug connector then testing the switch with a multimeter? There could be all at the same time, a shorted or broken switch wire, bad switch, a bad solenoid, and a burnt out bulb or combination of all those. The the switch, wiring and bulb need to be eliminated from the trouble shooting path. Check the connector at the solenoid.

- 33 replies

-

- overdrive switch

- overdrive

-

(and 1 more)

Tagged with:

-

Not sure if this was mentioned or not, You should look and ask questions about the floor. That water damage looks like it went all the way. The spring bushings (3 each side), bolts etc would be number one on the list if you don't choose to put in new springs. New springs though as Linda suggests is the best route. I put air bags and air shocks on our last Toy with a pump and remote gauge and switch in the cab for the bags. Usually ran them both at about 80lbs. If the bushings are 3 piece then they are not going to just pop out. It is possible to replace the bushings without pulling the springs. I gut the bushing so that just the outer shell is still in the spring (it's fun!). Then carefully with a hand operated hacksaw cut almost through the bushing shell on two sides then drive a small punch between the spring and shell. New ones can be pressed back in with a just smaller socket, a good clamp and some grease. The shackles are probably shot also. A great modification is to weld a square tube between the shackles, this keeps them from leaning side to side in turns etc. You can buy pre made. If you do it all yourself it is not a job for the faint of heart. A concrete floor. two heavy duty jack stands and a big floor jack, it's not too bad. You just do one side at a time. I am waiting for someone to try this product " Roadmaster Active Suspension ". I installed a pair on my F150, like night and day.

-

I think you are missing the bulb and plastic lens. The bulb I think is a T3-1/4 Glass Wedge Base available at any auto parts store. The socket you see is the bulb socket (red wire). There is also a rectangle shaped translucent plastic panel that sits at the bottom.

-

Knob should not spin at all. My bet is the wire is broken. The knob spinning probably means the shifter is now junk. Here is one on ebay, at least the pic might help https://www.ebay.com/itm/1989-1990-1991-1992-93-94-95-Toyota-Pickup-Automatic-Column-Shifter-OD-Switch/153324682197?hash=item23b2dcfbd5:g:4E8AAOSwb15cK27N:sc:USPSFirstClass!97396!US!-1:rk:2:pf:0

- 33 replies

-

- overdrive switch

- overdrive

-

(and 1 more)

Tagged with:

-

Ditto Odyssey 4x4. Make sure you tell them it is for a gas tank, I once had a counter person try to sell me a straight radiator type hose even though I told him I wanted hose for a gas tank. You might have to make some cuts in the ends of the old hoses to get them released. Slit the end of the hose then get a screwdriver into the slit and pry the hose away from the fitting. Older hoses tend to get rigamortis and sometimes have to be somewhat chopped up to get out. I have never felt it was a fun job. If your on your back watch out for the crude into your eyeball. Never use a drop light with a regular incandescent or CFL light bulb. I have a friend who was under his car working on a gas line, gas ran down his hand and arm to his body. He accidently knocked the drop light onto the floor breaking the bulb setting himself on fire!

-

So where from do they originate? Take some pictures of those locations. Here is a diagram for a 4runner, note the two vacuum lines going to the pump. Perhaps your pump does not need that valve. 4runners are different in some components. I know that the AC pumps are bigger so is the steering pump the same? Anyhow it looks like you have to stand on your head to see where the valve would be.

-

If A Seabee diagram is correctly depicting the location then isn't that where the PWR steering pump is located? Here is another diagram but it does not show the 17630. Question is does it actually cause a change in the pump or does it change the engine because of the extra load the pump puts on the engine in parking situations and low idle? I had a lean code also, needed a valve adjustment and the code never came back.

-

Your welcome, here is a guide to multi meter use, it seems pretty good but I did not completely read through it. https://randomnerdtutorials.com/how-to-use-a-multimeter/

- 9 replies

-

- remove 80 amp box fuse

- fuseable link

-

(and 2 more)

Tagged with:

-

The greenish corrosion is a red flag. Never seen that. Someone correct me if I am wrong, I believe the 80 amp is bolted in. You need to test it with a voltmeter making sure it has 12 volts on each side of it. Even so if where it bolts up it is corroded it could be a problem. Unbolt it, run a continuity test on it, if it's good clean everything up and bolt it back together. Disconnect your battery before you do all that. As Maineah said start at the battery cleaning all the posts and clamps etc. + and -. If your battery clamps are after market, the kind where the cable slips into a clamp take it apart, spread apart the wires of the cable and use a wire brush to remove the corrosion. I like to apply some Noalox® Anti-Oxidant Compound to the wires before reassembling. Another thing to check is your battery ground cables. There should be two ground wires, battery to engine and battery to chassis or engine to chassis. Rare that they have problems but worth a check. Your best friend and tool is a multitester!

- 9 replies

-

- remove 80 amp box fuse

- fuseable link

-

(and 2 more)

Tagged with:

-

Here is a conversion kit to make a non floater into a full floater, these start at year 1979 so that's a problem but you might give them a call and see what they say. You could allways put in a later year axle with the full floater kit. Did I mention Disc Brakes? https://frontrangeoffroadfab.com/full-floater-conversion/

-

Furnace Heater Trouble Shooting- Help Needed

Gulfstream Greg replied to Jules the Dolphin's topic in General Discussion

https://pdxrvwholesale.com/products/atwood-hydroflame-furnace-model-8516-ii-tune-up-kit And the manual https://dunesport.com/manuals/atwood-furnace.pdf I don't see a window in the manual for watching to see if you actually get spark.